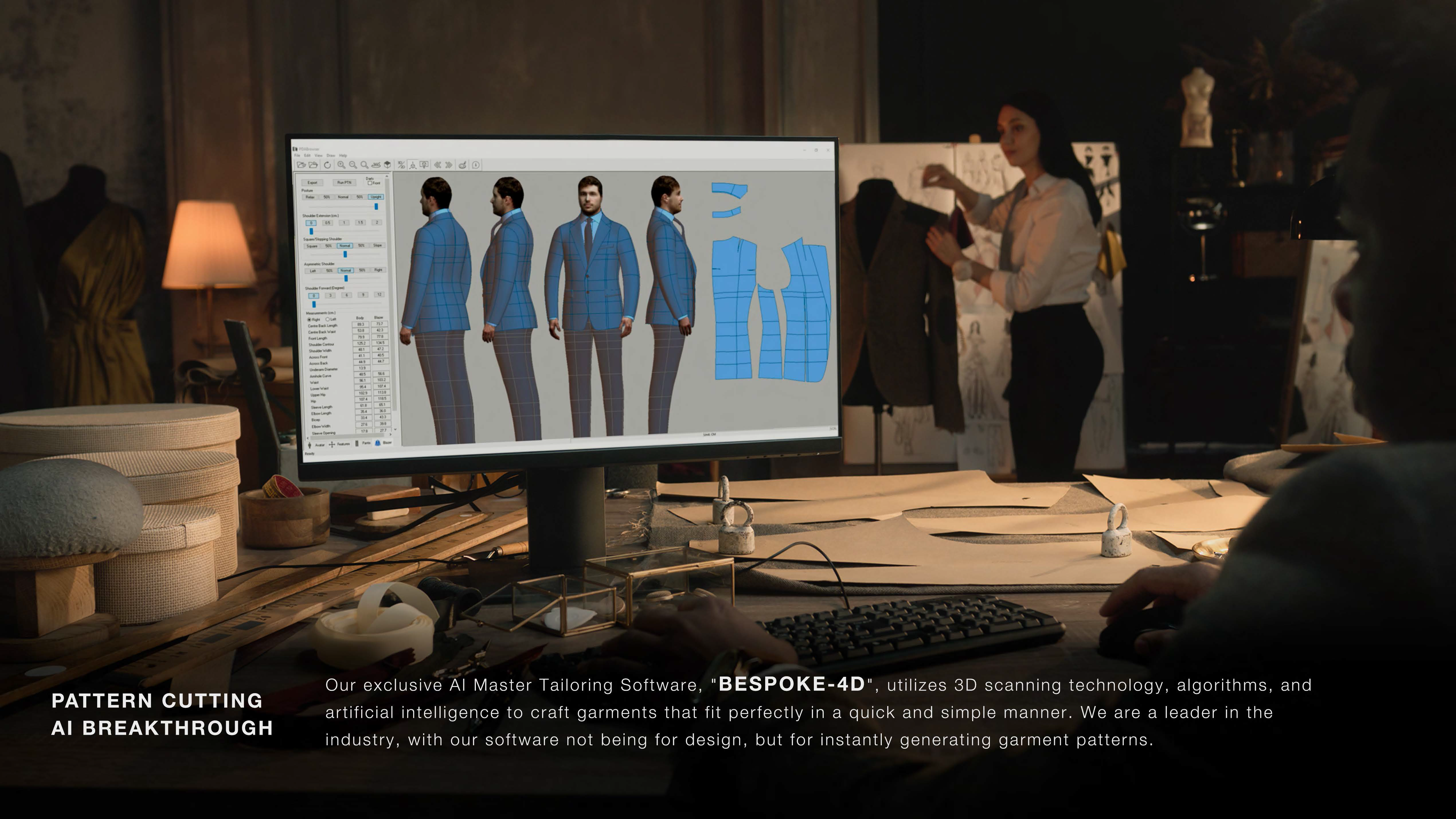

Our software Bespoke 4D

Sustainability with Bespoke 4D

The fashion industry is the 2nd most polluting business sector in the world and the biggest waster of fabrics. In France alone in 2019, at least 140 million pieces of clothing remained on the arms of brands. These are then sent to the landfill!

Our solution for a more sustainable production in fashion: Digitalization of the Know-How of Master Tailors for a personalized customization with our Bespoke 4D software. This means that the garment is made like a glove for each customer but can be produced on demand. Thus, we can reduce overproduction and avoid waste of fabrics.

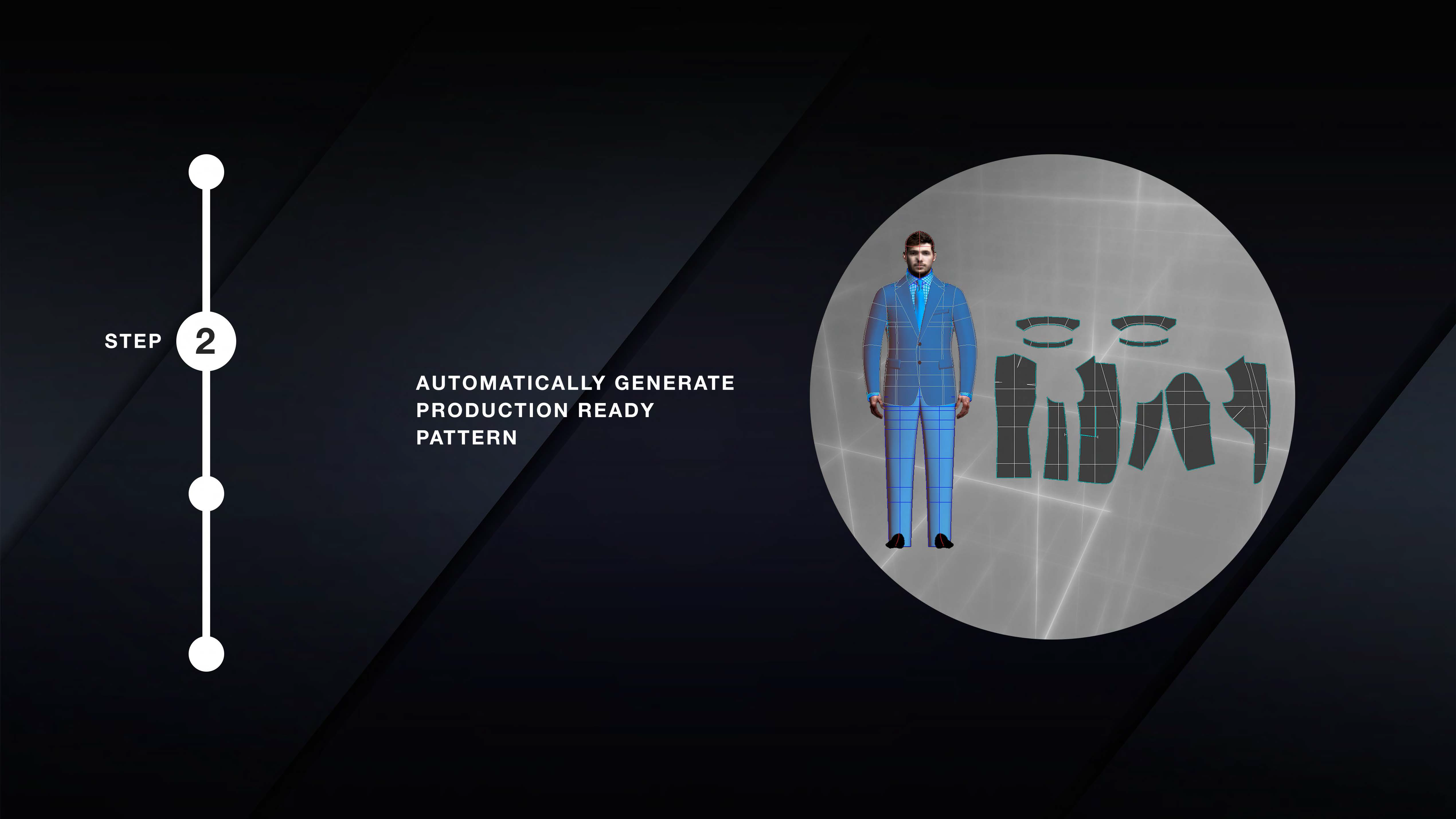

Bespoke 4D can generate production-ready patterns in 30 minutes with a Master-Tailor quality for any garment manufacturers. It’s a real democratization of personalized clothing accessible to a wide audience.

In general, the operational process of garment manufacturing is long and requires a lot of pattern adjustment. Our operational simplification with Bespoke 4D contributes to:

- A reduction of 95% of fabric waste.

- A drop in inventory of more than 90%.

- A shorter and quicker production process.

- With our personalised customization and production on demand, clothing manufacturers can avoid overproduction and also avoid sending garment to landfill.